(Early flying car – the Aerocar)

I’m excited, honored – and a bit nervous – about being a moderator for several sessions during Monday’s Passenger Experience Conference in Hamburg, Germany.

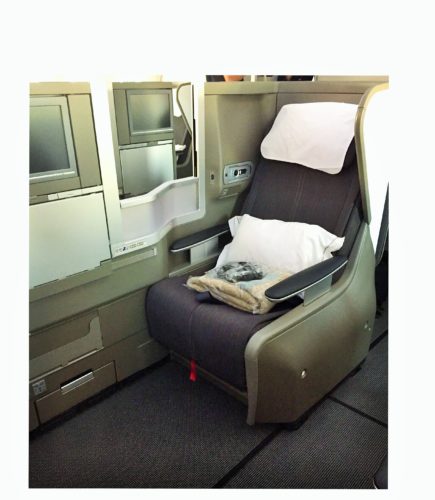

The topics my presenters will be tackling in the Covergence and Mobility stream range from how mobile technology might better (or ever) tie together the many ways we now have to travel through the world (bikes, taxis, car share, trains, planes, etc…) to how – and when – we might eat or do other things along the way.

I’ll be sharing notes, pictures and musings here and on Twitter (@hbaskas) about these presentations and the new and exciting products and ideas that are presented throughout the week at the Aircraft Interiors Expo and several related events being held in Hamburg this week.

Standy by and please feel free to send your questions to me here – or via Twitter (@hbaskas) – about what’s in store for getting to and from airports and for flying on airplanes.